Fill Out a Valid Electrical Panel Schedule Template

Form Specs

| Fact Name | Description |

|---|---|

| Purpose | The Electrical Panel Schedule form is used to document the layout and specifications of electrical circuits in a building. |

| Components | The form typically includes details such as circuit numbers, amperage ratings, and the devices connected to each circuit. |

| Safety Compliance | It helps ensure compliance with safety regulations and electrical codes to prevent hazards. |

| Usage | Electricians and contractors commonly use this form during the installation and inspection of electrical systems. |

| State Variations | Some states may have specific requirements or formats for the Electrical Panel Schedule, governed by local electrical codes. |

| Record Keeping | Maintaining an accurate Electrical Panel Schedule aids in future maintenance and upgrades of the electrical system. |

| Accessibility | The form should be easily accessible to anyone responsible for electrical work in the building. |

| Updates | It is important to update the schedule whenever changes are made to the electrical system. |

| Legal Requirement | In many jurisdictions, having an Electrical Panel Schedule may be a legal requirement for new constructions. |

| Consultation | Consulting with a licensed electrician is recommended when filling out this form to ensure accuracy and compliance. |

Dos and Don'ts

When filling out the Electrical Panel Schedule form, it's important to follow certain guidelines to ensure accuracy and compliance. Here’s a list of things you should and shouldn't do:

- Do double-check all electrical specifications before entering them.

- Do use clear and legible handwriting or type your entries.

- Do include all relevant information, such as panel location and load calculations.

- Do keep a copy of the completed form for your records.

- Don't leave any fields blank unless specified.

- Don't use abbreviations that might confuse the reader.

- Don't forget to sign and date the form where required.

- Don't submit the form without reviewing it for errors.

Other PDF Documents

How Many Pages Is a Tax Return Transcript - A Sample Tax Return Transcript provides a snapshot of tax information for a specific year.

Emotional Support Animal Letter From Therapist - The letter may include specific mention of the animal's name to identify it as the support animal.

To learn more about the importance and proper usage of the document, individuals can refer to additional resources such as the https://georgiaform.com/, which provides comprehensive insights into the Georgia Power of Attorney form and its legal implications.

Act of Donation of a Movable Louisiana - Clear language in the form helps prevent misunderstandings between parties involved.

Common mistakes

-

Missing Panel Identification: One common mistake is not clearly labeling the panel. Each panel should have a unique identification number or name to avoid confusion.

-

Incorrect Load Calculations: Failing to calculate the load correctly can lead to serious issues. It's important to ensure that the total load does not exceed the panel’s capacity.

-

Omitting Circuit Descriptions: Not providing clear descriptions for each circuit can create problems during installation and troubleshooting. Each circuit should specify what it powers.

-

Inaccurate Breaker Ratings: Using the wrong breaker ratings can be hazardous. Ensure that the ratings match the requirements of the circuits they protect.

-

Ignoring Local Codes: Every area has specific electrical codes. Neglecting to adhere to these can result in fines or unsafe installations.

-

Not Updating the Schedule: Failing to update the panel schedule after changes can lead to confusion. Always keep it current with any modifications to the system.

-

Overlooking Future Expansion: Not considering future needs can limit the system’s effectiveness. Plan for potential growth by leaving room for additional circuits.

Documents used along the form

The Electrical Panel Schedule form is a critical document for managing electrical systems within a building. However, several other forms and documents often accompany it to ensure comprehensive planning, installation, and maintenance of electrical systems. Below is a list of these essential documents, each serving a unique purpose in the overall electrical management process.

- Load Calculation Worksheet: This document helps determine the total electrical load requirements for a building. It factors in all electrical devices and systems to ensure the electrical panel can handle the anticipated demand.

- Electrical Plan Drawings: These detailed drawings provide a visual representation of the electrical layout in a building, including the location of outlets, switches, and the main panel. They are essential for installation and future modifications.

- Single Line Diagram: This simplified representation of the electrical system shows the connections and flow of electricity. It helps in understanding how various components interact and is crucial for troubleshooting and maintenance.

- Circuit Directory: This document lists all circuits connected to the electrical panel, detailing which areas or devices each circuit powers. It aids in quick identification during repairs or upgrades.

- Load Balancing Report: This report analyzes the distribution of electrical loads across the panel. Proper load balancing prevents overheating and potential failures, ensuring safety and efficiency.

- Inspection Report: After installation or maintenance, an inspection report documents the condition and compliance of the electrical system with local codes and standards. It ensures safety and reliability.

- Operating Agreement: The Operating Agreement is essential for Ohio-based LLCs as it details the management structure and operational procedures of the business. It's important for clarifying the rights and responsibilities of members, making it a key component in maintaining order within the company. For more details, you can refer to Ohio PDF Forms.

- Maintenance Log: Keeping a record of all maintenance activities helps track the performance and longevity of the electrical system. This log can highlight recurring issues and inform future maintenance strategies.

- As-Built Drawings: These drawings reflect the final installation of the electrical system, including any changes made during construction. They are essential for future renovations or repairs.

- Permits and Approvals: Before any electrical work can commence, necessary permits must be obtained from local authorities. This documentation ensures that all work complies with safety regulations and building codes.

Each of these documents plays a vital role in the effective management of electrical systems. Together, they provide a comprehensive framework for planning, executing, and maintaining safe and efficient electrical installations.

Misconceptions

Understanding the Electrical Panel Schedule form is crucial for effective electrical management. However, several misconceptions can lead to confusion. Here are five common misconceptions:

- It’s only for large buildings. Many believe that the Electrical Panel Schedule is necessary only for large commercial buildings. In reality, all facilities, regardless of size, benefit from having a clear electrical panel schedule to ensure safety and compliance.

- It’s a one-time document. Some think that once the Electrical Panel Schedule is created, it never needs updating. This is incorrect. Changes in electrical load, equipment, or configuration require regular updates to the schedule.

- It’s too complicated to understand. While the form may seem technical, it is designed to be user-friendly. With a little guidance, anyone can learn to read and utilize the schedule effectively.

- Only electricians need to use it. This form is not just for electricians. Facility managers, safety officers, and even emergency responders can benefit from understanding the electrical panel schedule.

- It’s not necessary for safety. Some may underestimate the importance of the Electrical Panel Schedule in maintaining safety. However, it plays a vital role in identifying potential hazards and ensuring proper load management.

By clarifying these misconceptions, individuals can better appreciate the importance of the Electrical Panel Schedule in managing electrical systems safely and efficiently.

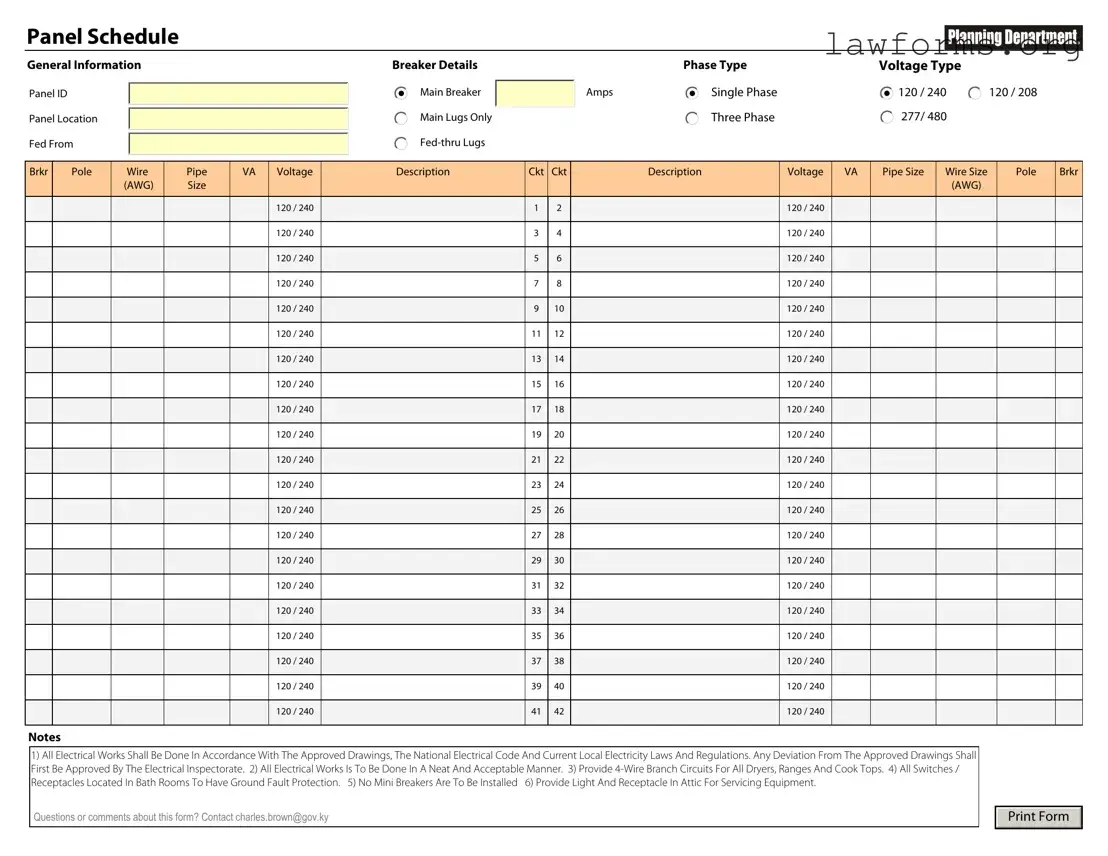

Preview - Electrical Panel Schedule Form

Panel Schedule

General Information

Panel ID

Panel Location

Fed From

Breaker Details

Main Breaker

Main Lugs Only

|

Phase Type |

Voltage Type |

|

Amps |

Single Phase |

120 / 240 |

120 / 208 |

|

Three Phase |

277/ 480 |

120 / 240 |

|

|

|

Brkr |

Pole |

Wire |

Pipe |

VA |

Voltage |

Description |

Ckt |

Ckt |

Description |

Voltage |

VA |

Pipe Size |

Wire Size |

Pole |

Brkr |

|

|

(AWG) |

Size |

|

|

|

|

|

|

|

|

|

(AWG) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

1 |

2 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

3 |

4 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

5 |

6 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

7 |

8 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

9 |

10 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

11 |

12 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

13 |

14 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

15 |

16 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

17 |

18 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

19 |

20 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

21 |

22 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

23 |

24 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

25 |

26 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

27 |

28 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

29 |

30 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

31 |

32 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

33 |

34 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

35 |

36 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

37 |

38 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

39 |

40 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 / 240 |

|

41 |

42 |

|

120 / 240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes

1)All Electrical Works Shall Be Done In Accordance With The Approved Drawings, The National Electrical Code And Current Local Electricity Laws And Regulations. Any Deviation From The Approved Drawings Shall First Be Approved By The Electrical Inspectorate. 2) All Electrical Works Is To Be Done In A Neat And Acceptable Manner. 3) Provide

Receptacles Located In Bath Rooms To Have Ground Fault Protection. 5) No Mini Breakers Are To Be Installed 6) Provide Light And Receptacle In Attic For Servicing Equipment.

Questions or comments about this form? Contact charles.brown@gov.ky

Print Form

Key takeaways

Here are some important points to remember when filling out and using the Electrical Panel Schedule form:

- Ensure all information is accurate. Double-check the details before submission.

- Include the correct panel name and number for easy identification.

- List all circuits clearly, specifying their designated loads.

- Use consistent units of measurement for all electrical loads.

- Document any special notes or instructions that may be relevant to the panel.

- Keep the schedule updated as changes occur in the electrical system.

- Refer to local codes and regulations to ensure compliance when filling out the form.

By following these key takeaways, you can effectively manage your electrical panel schedule and maintain a safe electrical system.

Similar forms

The Electrical Panel Schedule form is an essential tool in electrical design and management. Its purpose is to provide a clear overview of the electrical distribution system within a building. Several other documents share similarities with the Electrical Panel Schedule, each serving a specific function in the realm of electrical systems. Here are nine documents that are comparable:

- Load Calculation Sheet: This document outlines the expected electrical load for a building, much like the panel schedule, which details how that load is distributed across circuits.

- Circuit Directory: Similar to the panel schedule, the circuit directory lists all circuits in a panel, indicating their purpose and which devices they serve.

- One-Line Diagram: This visual representation of the electrical system shows how components are connected, paralleling the panel schedule's role in mapping out electrical distribution.

- Wiring Diagram: While the panel schedule organizes circuit information, the wiring diagram illustrates how wires connect devices, providing a complementary view of the system.

- Panelboard Installation Instructions: These instructions guide the installation of panelboards, similar to how the panel schedule provides operational guidance for managing electrical loads.

- Electrical Service Agreement: This document outlines the terms of service with the utility provider, akin to the panel schedule's role in defining the building's electrical needs.

- Energy Management Plan: This plan focuses on optimizing energy use, much like the panel schedule, which helps in monitoring and managing electrical loads effectively.

- California Civil Form: The required Civil Case Cover Sheet (CM-010) assists in properly initiating civil cases, ensuring essential information is conveyed. For more details, visit https://californiadocsonline.com/california-civil-form.

- Maintenance Log: This log tracks maintenance activities on electrical systems, similar to how the panel schedule helps in managing circuit performance and identifying issues.

- Safety Inspection Report: This report assesses compliance with safety standards, paralleling the panel schedule’s role in ensuring that circuits are properly documented and managed.

Understanding these documents can enhance your grasp of electrical systems and improve your ability to manage them effectively.