Fill Out a Valid Pre Trip Inspection Checklist Template

Form Specs

| Fact Name | Description |

|---|---|

| Purpose | The Pre Trip Inspection Checklist is designed to ensure that vehicles are safe and roadworthy before they are used for transportation. |

| Components | This checklist typically includes sections for inspecting the engine, brakes, lights, tires, and other critical vehicle systems. |

| Legal Requirement | In many states, federal regulations require commercial drivers to complete a pre-trip inspection before operating a vehicle. |

| Documentation | Drivers must document their inspections, noting any defects or issues found during the process. |

| Frequency | The inspection must be performed daily or before each trip, depending on the vehicle's use and state regulations. |

| State-Specific Laws | In California, for example, the California Vehicle Code Section 34501 mandates that commercial vehicles undergo a pre-trip inspection. |

| Safety Impact | Regular use of the checklist can significantly reduce the risk of accidents caused by vehicle malfunctions. |

Dos and Don'ts

When preparing to fill out the Pre Trip Inspection Checklist form, it's essential to approach the task with care and attention. Here’s a helpful list of things you should and shouldn’t do:

- Do read the entire checklist before starting. Familiarity with each item helps ensure nothing is overlooked.

- Do take your time. Rushing can lead to mistakes that might compromise safety.

- Do check off items as you complete them. This practice keeps you organized and ensures thoroughness.

- Do use clear and legible handwriting. This makes it easier for others to read your notes and findings.

- Don’t skip items, even if they seem minor. Every part of the vehicle is important for safety.

- Don’t use abbreviations or shorthand unless you are sure everyone will understand them. Clarity is key.

- Don’t ignore warning signs or unusual findings. Report them immediately to ensure they are addressed.

- Don’t forget to sign and date the form after completing it. This adds accountability and verifies the inspection was done.

By following these guidelines, you can help ensure that your Pre Trip Inspection Checklist is filled out accurately and effectively, promoting safety on the road.

Other PDF Documents

Da - This hand receipt is important both for operational readiness and for financial accountability.

When transferring ownership of a vehicle or vessel in California, it is crucial to complete the necessary paperwork, including the California Form REG 262. This form serves as a Vehicle/Vessel Transfer and Reassignment Form and must accompany the title or application for a duplicate title. To understand the specifics of the form and its requirements, you can visit https://californiadocsonline.com/california-fotm-reg-262-form, ensuring that both buyers and sellers are protected and compliant with state laws during the transaction.

Tst Test - The result must be signed by the healthcare professional reading or reporting the outcome.

U.S. Corporation Income Tax Return - Filing Form 1120 correctly will strengthen a corporation's financial standing and tax compliance.

Common mistakes

-

Incomplete Information: Many individuals fail to fill out all required fields. This can lead to delays or complications during inspections. Ensure every section is addressed fully.

-

Inaccurate Details: Providing incorrect information about vehicle conditions or maintenance history is common. Double-check all entries for accuracy before submission.

-

Neglecting Signature: Some forget to sign the checklist. A signature confirms that the inspection was completed. Always remember to sign and date the form.

-

Rushing the Process: Taking shortcuts during the inspection can lead to missed issues. Take your time to thoroughly inspect each item on the checklist.

Documents used along the form

The Pre Trip Inspection Checklist form is an essential document for ensuring vehicle safety and compliance before operation. Several other forms and documents complement this checklist to enhance safety, maintenance, and regulatory compliance. Below is a list of these related documents.

- Vehicle Maintenance Log: This document records all maintenance activities performed on the vehicle, including oil changes, tire rotations, and repairs. It helps track the vehicle's service history.

- Driver Qualification File: This file contains important information about the driver's qualifications, including licenses, certifications, and training records. It ensures that only qualified individuals operate the vehicle.

- Daily Vehicle Inspection Report: Similar to the Pre Trip Inspection Checklist, this report is filled out daily to document the condition of the vehicle and any issues that need addressing.

- Accident Report Form: This form is used to document any accidents involving the vehicle. It includes details about the incident, damages, and any injuries sustained.

- Quitclaim Deed: This document can be important when transferring property ownership without the guarantee of the title's validity. For more information on how to obtain one, visit Ohio PDF Forms.

- Fuel Consumption Log: This log tracks fuel usage and helps monitor efficiency. It provides insights into fuel costs and vehicle performance over time.

- Roadside Assistance Agreement: This document outlines the terms of service for roadside assistance. It provides details on how to access help in case of a breakdown or emergency.

- Compliance Review Checklist: This checklist is used to ensure adherence to regulatory requirements. It helps identify areas needing attention to maintain compliance with safety standards.

Utilizing these documents in conjunction with the Pre Trip Inspection Checklist can significantly improve vehicle safety and operational efficiency. Each document serves a specific purpose, contributing to a comprehensive approach to vehicle management.

Misconceptions

Misconceptions about the Pre Trip Inspection Checklist form can lead to misunderstandings about its purpose and importance. Here are eight common misconceptions, along with clarifications for each.

- It is optional for drivers to complete the checklist. Many believe that the checklist is merely a suggestion. In reality, it is a critical safety measure required by law to ensure vehicles are roadworthy before departure.

- Only new drivers need to use the checklist. Some think that experienced drivers can skip the checklist. However, all drivers, regardless of experience, should perform inspections to maintain safety standards.

- The checklist is only for commercial vehicles. While it is mandatory for commercial drivers, personal vehicle owners can also benefit from performing a pre-trip inspection to enhance safety.

- Completing the checklist takes too much time. Many underestimate the efficiency of the checklist. A thorough inspection can be completed in a relatively short amount of time, ultimately saving time by preventing breakdowns.

- All items on the checklist are the same for every vehicle. Some assume that the checklist is uniform across all vehicles. In fact, different vehicles may require specific checks based on their type and usage.

- Once the checklist is completed, it does not need to be revisited. There is a misconception that a completed checklist is sufficient for future trips. Drivers should regularly review and update their inspections, especially after significant vehicle changes.

- Only mechanical issues need to be reported. Some focus solely on mechanical aspects and neglect other important areas. The checklist also addresses safety equipment, lights, and even cleanliness, all of which are crucial for safe travel.

- Drivers can rely on others to perform the inspection. Many believe they can delegate this responsibility. Ultimately, it is the driver's duty to ensure the vehicle is safe, and personal accountability is essential.

Understanding these misconceptions can help promote safer driving practices and ensure that all vehicles are properly inspected before hitting the road.

Preview - Pre Trip Inspection Checklist Form

Class A CDL

®

®

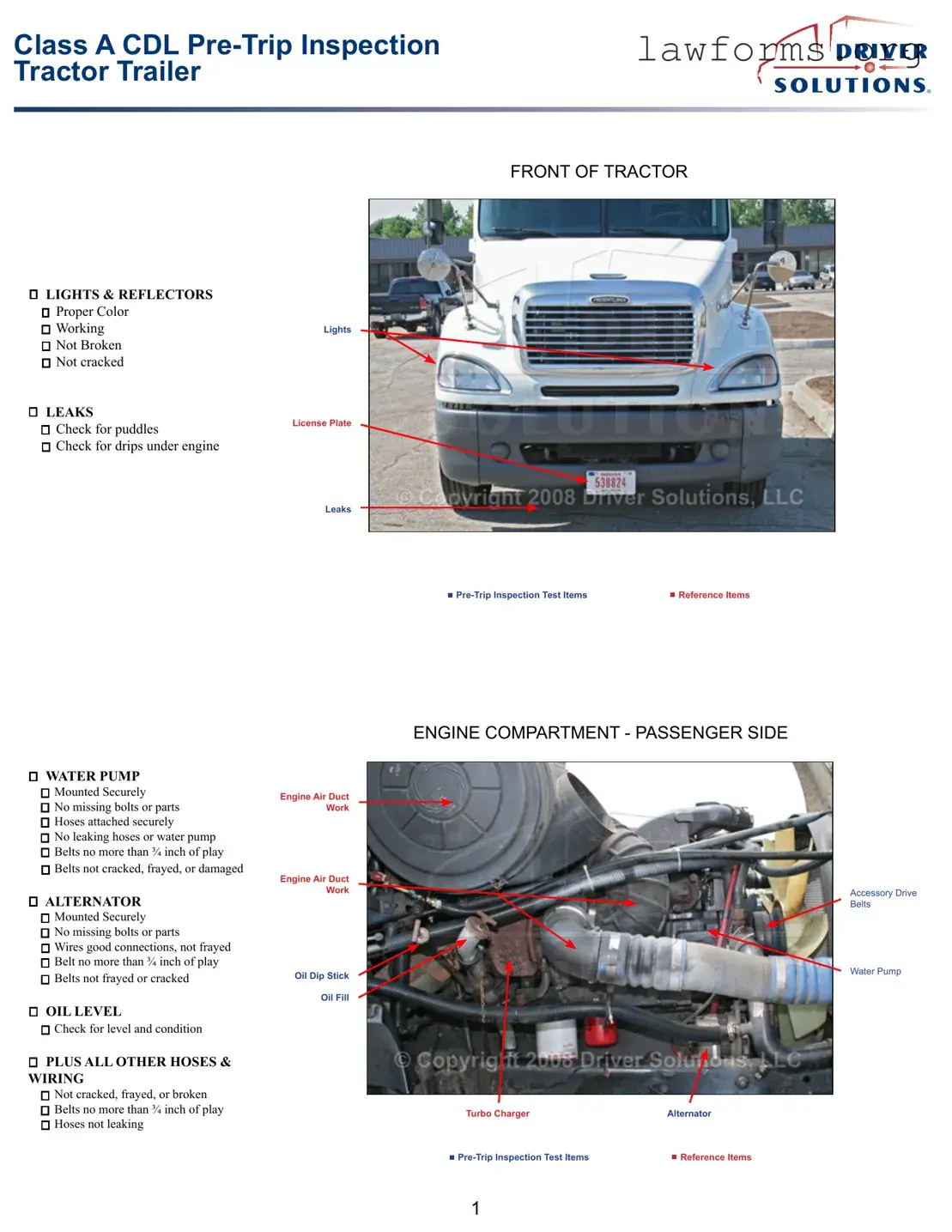

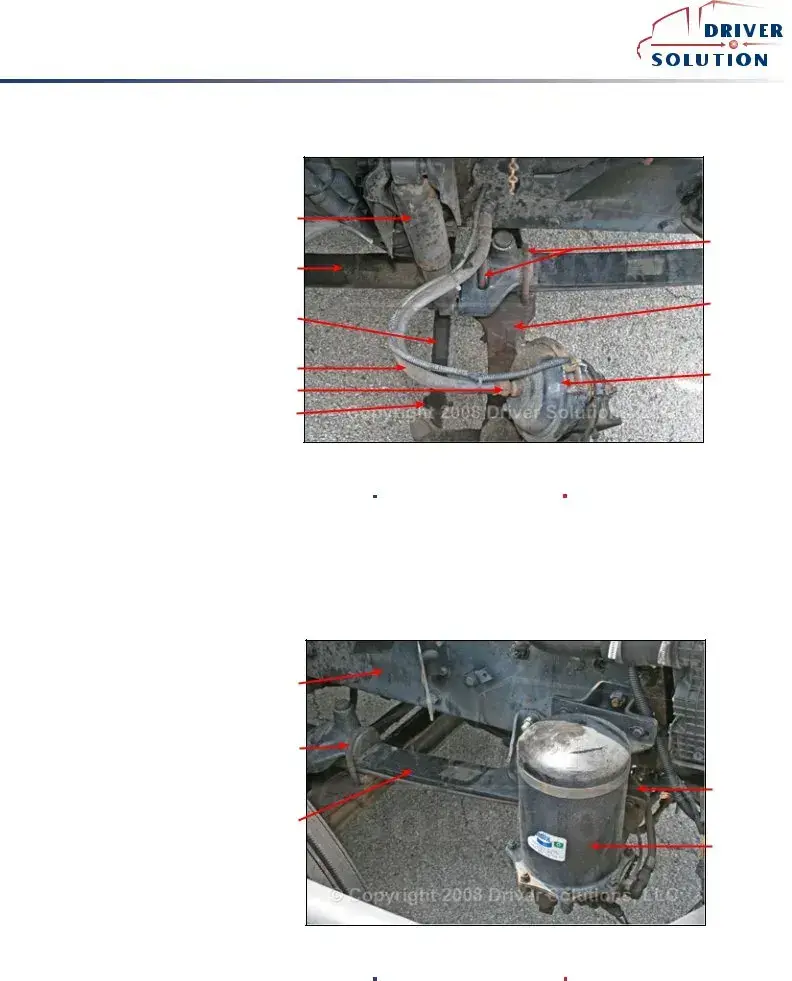

FRONT OF TRACTOR

LIGHTS & REFLECTORS o Proper Color

o Working

o Not Broken o Not cracked

LEAKS

o Check for puddles

o Check for drips under engine

Lights

License Plate

Leaks

Reference Items |

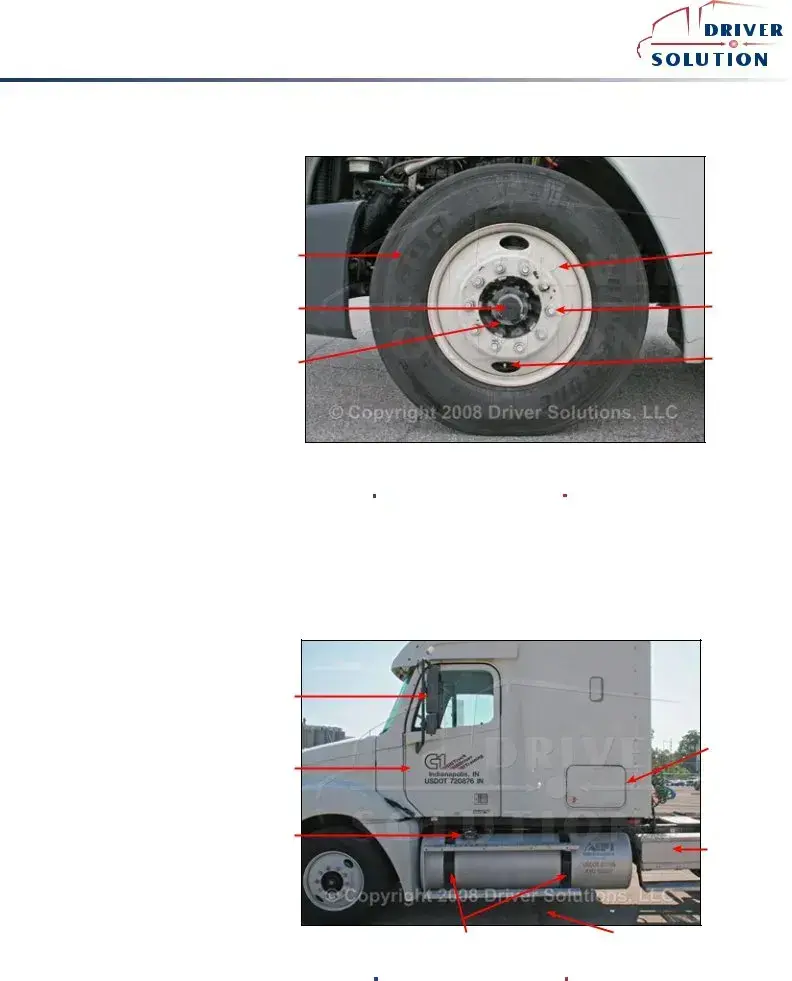

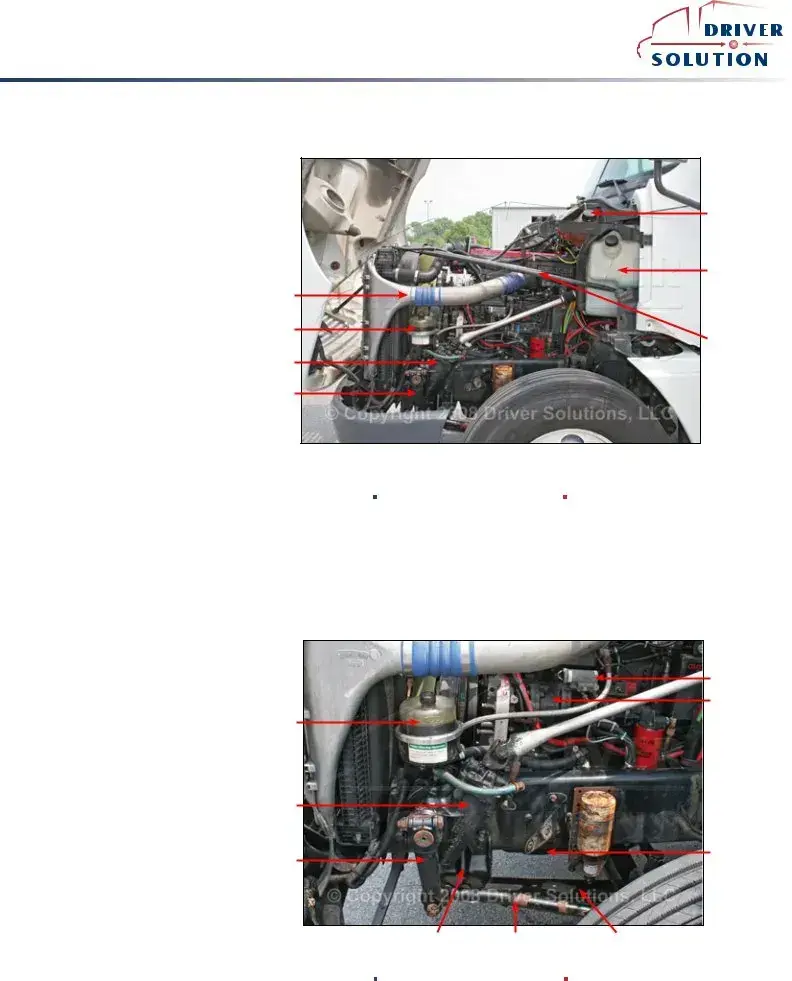

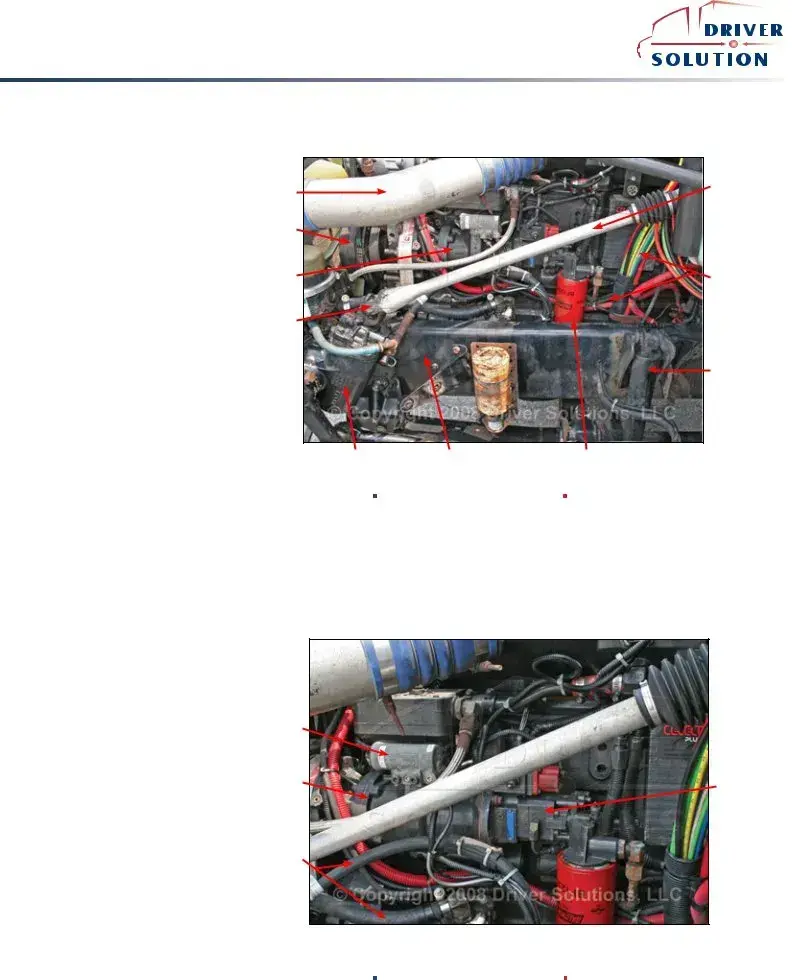

ENGINE COMPARTMENT - PASSENGER SIDE

WATER PUMP o Mounted Securely

o No missing bolts or parts o Hoses attached securely

o No leaking hoses or water pump o Belts no more than ¾ inch of play

o Belts not cracked, frayed, or damaged

ALTERNATOR

o Mounted Securely

o No missing bolts or parts

oWires good connections, not frayed

oBelt no more than ¾ inch of play

oBelts not frayed or cracked

OIL LEVEL

oCheck for level and condition

PLUS ALL OTHER HOSES & WIRING

oNot cracked, frayed, or broken

oBelts no more than ¾ inch of play o Hoses not leaking

Engine Air Duct Work

Engine Air Duct Work

Oil Dip Stick

Oil Fill

|

Accessory Drive |

|

Belts |

|

Water Pump |

Turbo Charger |

Alternator |

Reference Items |

1

Class A CDL

®

®

ENGINE COMPARTMENT - DRIVER SIDE

COOLANT

oCheck for level and condition

oHoses attached and not leaking

POWER STEERING RESERVOIR

oMounted properly

oHoses attached and not leaking

oCheck for level and condition

AIR COMPRESSOR

oMounted Securely

oNo missing bolts or parts

oNo air leaks at lines

oCheck if gear or belt driven

oBelt no more than ¾ inch of play

oBelts not cracked or frayed

STEERING GEAR BOX

oMounted properly

oNo missing parts, nuts or bolts o Lines and hoses not leaking or broken

|

Engine Coolant |

|

Reservoir |

|

Windsheild |

|

Washer Fluid |

|

Reservoir |

Engine Air Duct |

|

Work |

|

Power Steering |

|

Reservoir |

Radiator Brace |

|

|

Steering Gear |

|

Box |

|

Pitman Arm |

|

Reference Items |

POWER STEERING RESERVOIR |

ENGINE COMPARTMENT - DRIVER SIDE CON’T |

||

|

|

|

|

o Mounted properly |

|

|

|

o Hoses attached and not leaking |

|

|

|

o Check for level and condition |

|

|

|

AIR COMPRESSOR |

|

|

|

o Mounted Securely |

Power Steering |

|

|

o No missing bolts or parts |

|

|

|

Reservoir |

|

|

|

o No air leaks at lines |

|

|

|

o Check if gear or belt driven |

|

|

|

o Belt no more than ¾ inch of play |

|

|

|

o Belts not cracked or frayed |

|

|

|

STEERING GEAR BOX |

Steering Gear |

|

|

Box |

|

|

|

o Mounted properly |

|

|

|

o No missing parts, nuts or bolts |

|

|

|

o Lines and hoses not leaking or |

Pitman Arm |

|

|

broken |

|

|

|

|

|

|

|

STEERING LINKAGE |

|

|

|

o Pitman arm, Drag link, Steering |

|

|

|

knuckle, Tie rods and tie rod ends |

|

|

|

o Not cracked, bent or broken |

Spring Mount |

Drag Link |

Leaf Spring |

o Castle nuts and cotter pins |

|

|

|

o Not missing and in place |

|

|

|

Reference Items |

Air Governor

Air Compressor

Engine Oil Pan

2

Class A CDL

®

®

AIR COMPRESSOR o Mounted Securely

o No missing bolts or parts o No air leaks at lines

o Check if gear or belt driven

o Belt no more than ¾ inch of play o Belts not cracked or frayed

STEERING GEAR BOX

o Mounted properly

oNo missing parts, nuts or bolts o Lines and hoses not leaking or broken

ENGINE COMPARTMENT - DRIVER SIDE CON’T

Engine Air Duct

Work

Fan Belts

Gear Driven Air

Compressor

Steering

Steering Column

Additional Hoses & Wiring

Shock Absorber

Steering Gear Box |

Frame Rail |

Fuel Filter |

Reference Items |

||

ENGINE COMPARTMENT - AIR COMPRESSOR

AIR COMPRESSOR o Mounted Securely

o No missing bolts or parts o No air leaks at lines

o Check if gear or belt driven

o Belt no more than ¾ inch of play o Belts not cracked or frayed

Air Governor

Gear Driven Air Compressor

Hoses

Fuel Pump

Reference Items |

3

Class A CDL

®

®

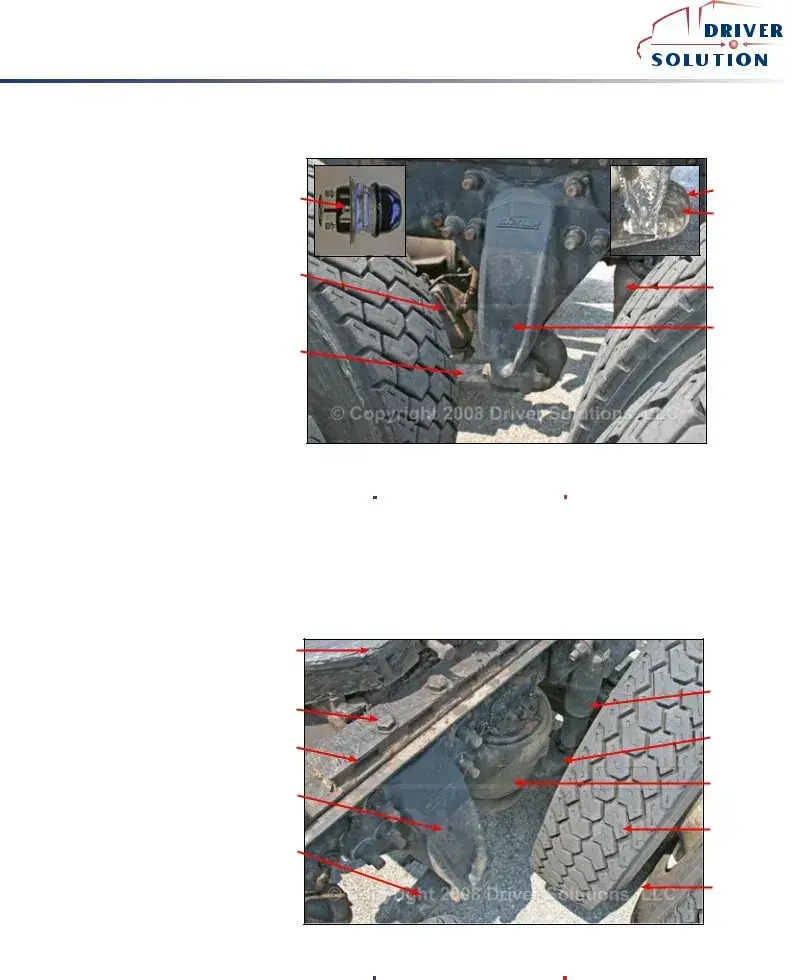

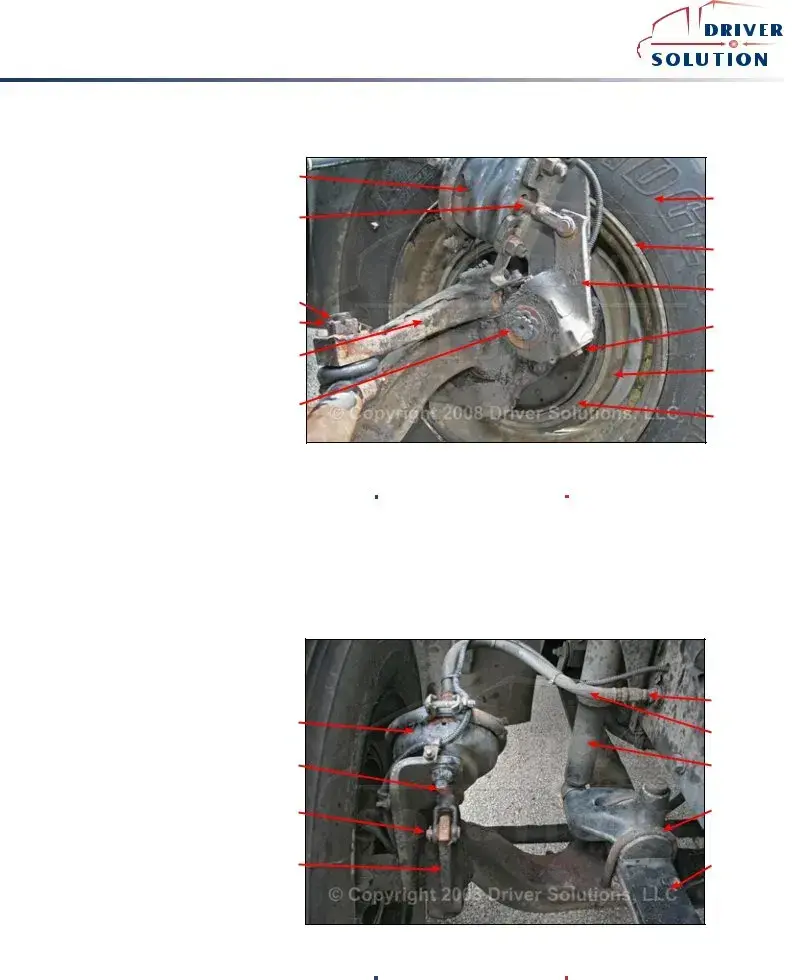

FRONT SUSPENSION

LEAF SPRINGS

o Not shifted or out of place

oNot cracked, broken or missing

SPRING MOUNTS

oMounted securely- front, back, and

oNot cracked or broken

SHOCK ABSORBER

oMounted Securely

oNot bent or dented o Not leaking

Shock Absorber

Leaf Spring

Tie Rod

Air Hose

Air LIne

Tie Rod End

Axle |

Service Brake |

Chamber |

Reference Items |

LEAF SPRINGS

o Not shifted or out of place

oNot cracked, broken or missing

SPRING MOUNTS

oMounted securely- front, back, and

oNot cracked or broken

SHOCK ABSORBER

oMounted Securely

oNot bent or dented o Not leaking

FRONT SUSPENSION CON’T

Frame Rail

Leaf Spring

Air Dryer location varies depending on model.

Located either behind the front bumper or behind the fuel tank.

Reference Items |

4

Spring Mount

Air Dryer

Class A CDL

®

®

HOSES AND LINES |

|

FRONT BRAKES |

|

|

|

||

o Mounted securely |

Service Brake |

|

|

o |

Not leaking |

|

|

o |

Not cracked or frayed |

Chamber |

|

|

Tire |

||

|

|

|

|

CHAMBER |

Push Rod |

|

|

o Mounted securely |

|

|

|

o Not dented or damaged |

|

Wheel |

|

o |

Not leaking |

|

|

SLACK ADJUSTER |

|

Slack Adjuster |

|

o |

No more than 1 inch of free play at |

Castle Nut |

|

the push rod with the brakes released. |

Cotter Pin |

Adjustment Nut |

|

o |

Not bent, broken, loose, or missing |

|

|

|

|

||

parts |

Steering |

|

|

|

|

Knuckle |

Brake Drum |

DRUMS |

|

||

|

|

||

o |

Not cracked, broken or dented |

|

|

o |

No oil leaking from inner oil seal, |

Snap Ring |

|

free of debris |

|

Brake Lining |

|

LININGS |

|

|

|

oNo cracked, broken or missing parts o Not less than ¼ inch in thickness

Reference Items |

HOSES AND LINES o Mounted securely o Not leaking

o Not cracked or frayed

CHAMBER

o Mounted securely

oNot dented or damaged

oNot leaking

SLACK ADJUSTER

oNo more than 1 inch of free play at the push rod with the brakes released.

oNot bent, broken, loose, or missing parts

DRUMS

oNot cracked, broken or dented

oNo oil leaking from inner oil seal, free of debris

LININGS

oNo cracked, broken or missing parts

oNot less than ¼ inch in thickness

FRONT BRAKES CON’T

Service Brake

Chamber

Push Rod

Clevis Pin &

Cotter Pin

Slack Adjuster

Reference Items |

Air Line

Air Hose

Shock Absorber

Spring

5

Class A CDL

®

®

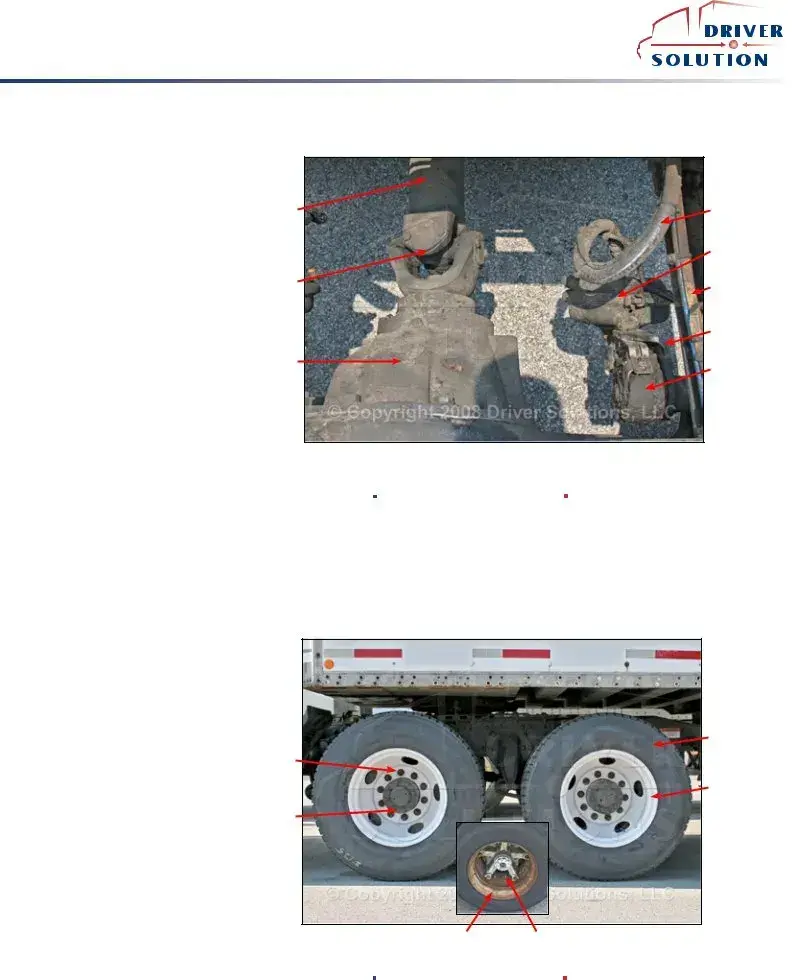

FRONT WHEEL

TIRES

oProper inflation – company or manufacturer specification

o No bulges, cuts, or retreads

o Minimum tread depth of 4/32”

RIMS

oNot bent, cracked, No welding repairs.

LUG NUTS

oNone are missing

oTight – no shinny threads, or rust trails

OUTER HUB OIL SEALS

oNot leaking, no missing bolts o Proper oil level

Tire |

Wheel |

|

Hub Oil |

Lug Nut |

|

Reservior |

||

|

||

Outer Hub |

Valve Cap |

|

Oil Seal |

|

Reference Items |

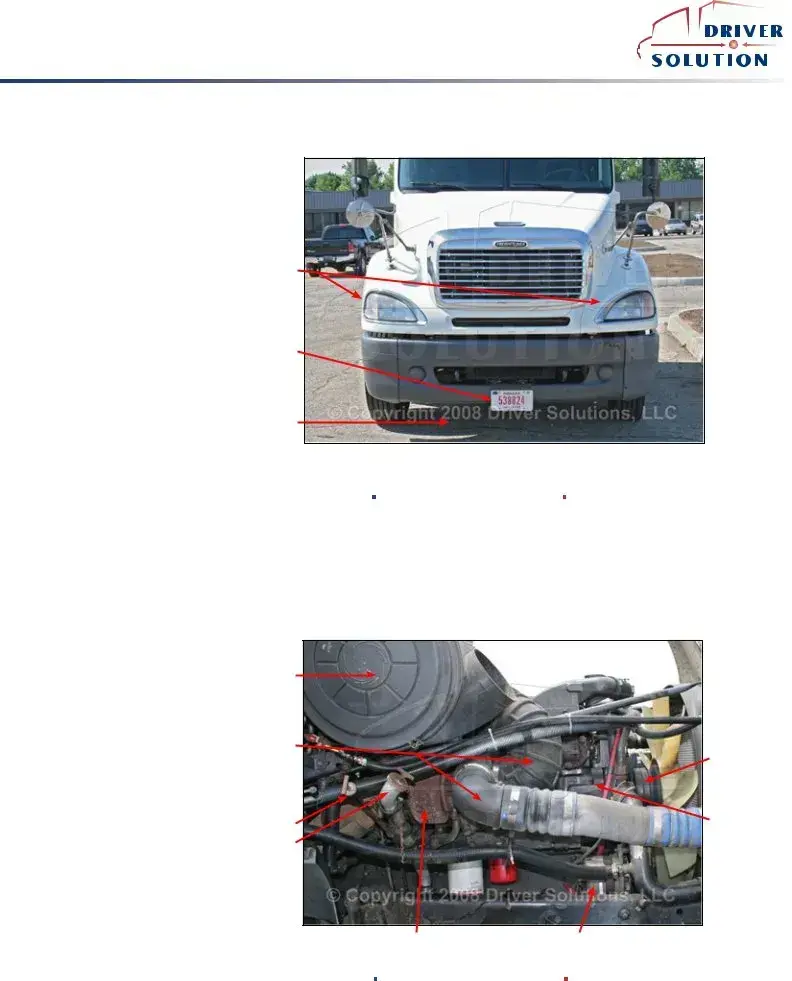

DRIVER FUEL AREA

DRIVER’S DOOR

oDoor opens and closes properly

oSeal is in good condition

DRIVER’S MIRRORS

oClean and free of obstruction

oNot cracked, broken, or damaged

oMounted securely

FUEL TANK

oMounted securely

o Not leaking

o Seal in cap OK

Mirror |

Storage |

Compartment |

Door |

Cap & Seal |

Battery Box & |

Cover |

Saddle Mounts |

Leaks |

Reference Items |

6

Class A CDL

®

®

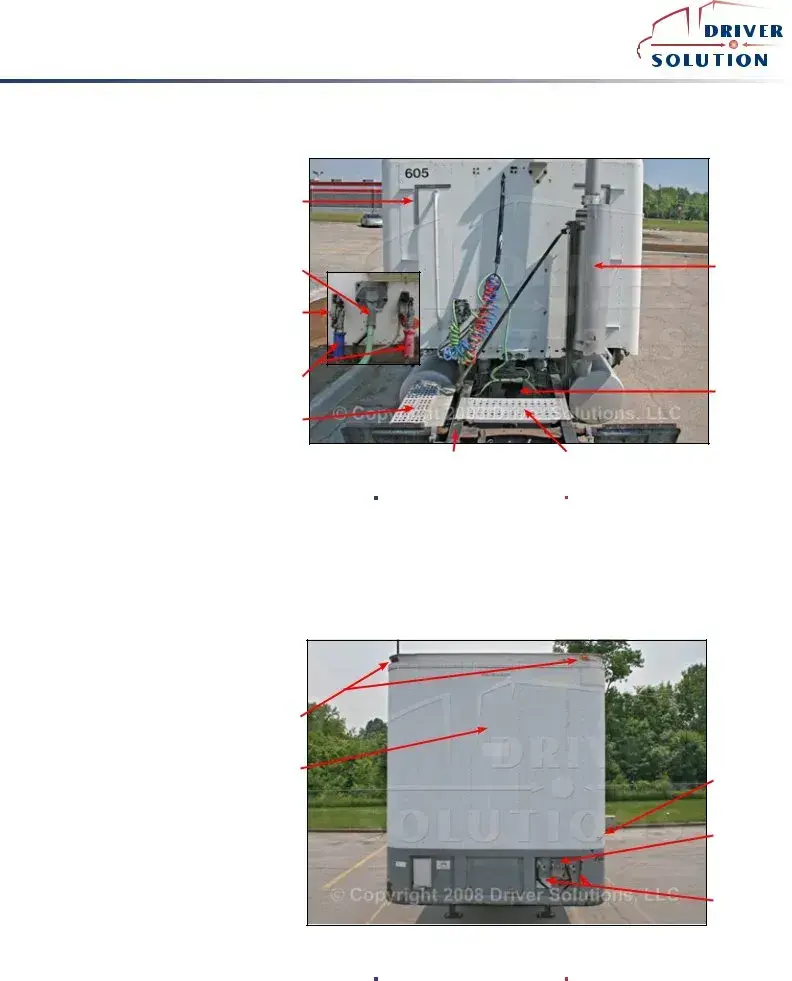

AIR LINES & ELECTRIC LINE o Not cracked, frayed, cut, or kinked o Mounted securely at the glad hands o Not leaking

BEHIND THE CAB

BATTERY BOX & BATTERIES o Box is mounted properly

o Batteries are secure in the box o Lid secure

o Connections not corroded

CATWALK

o Mounted properly

oNot, missing, or damaged

oFree of obstructions

DRIVE SHAFT

oNot bent, or damaged

oCoupling,

EXHAUST SYSTEM

oSecurely mounted

oNot dented or damaged

oNot leaking

FRAME

oNot cracked, or damaged

oNo missing bolts

oNo illegal welds

LIGHTS & REFLECTORS

oClean and working

Lights & |

|

Reflectors |

|

Electrical Line |

Exhaust |

Glad Hand |

|

Service & |

|

Emergency |

|

Airlines |

Drive Shaft |

|

|

Battery Box & |

|

Batteries |

|

Frame |

Catwalk |

Reference Items |

FRONT OF TRAILER

HEADER BOARD

oNo holes or missing rivets

LIGHTS & REFLECTORS

oNone broken, cracked, or missing

oWorking and proper color of amber

Lights |

Header Board |

Height Sticker

Electric Hookup

Air Line

Reference Items |

7

Class A CDL

®

®

DRIVE AXLE SUSPENSION

CONTROL ARM MOUNT o Mounted securely

o Not bent, broken or damaged

CONTROLARM

oMounted securely – front, back, and

o Not cracked, or broken

SHOCK ABSORBER

o Mounted Securely

oNot bent, dented or leaking

TORSION BAR

oMounted Securely

oNot bent, broken or damaged

AIR BAGS

oMounted Securely

o Not leaking

Spring Brake |

Torsion Bar |

|

|

Chamber |

Control Arm |

|

|

Spring Brake |

|

Chamber |

Air Bag |

|

|

|

Control Arm |

|

Mount |

Control Arm |

|

Reference Items |

DRIVE AXLE SUSPENSION CON’T & FIFTH WHEEL

CONTROL ARM MOUNT o Mounted securely

o Not bent, broken or damaged

CONTROLARM

oMounted securely – front, back, and

o Not cracked, or broken

SHOCK ABSORBER

o Mounted Securely

oNot bent, dented or leaking

TORSION BAR

oMounted Securely

oNot bent, broken or damaged

AIR BAGS

oMounted Securely

o Not leaking

Skid Plate |

|

|

Shock Absorber |

Mounting |

|

Bolts |

|

Locking |

Spring |

|

|

Pins |

|

Control Arm |

Air Bag |

|

|

Mount |

|

|

Tire |

Control Arm |

|

|

Space |

Reference Items |

8

Class A CDL

®

®

HOSES AND LINES o Mounted securely o Not leaking

o Not cracked or frayed

CHAMBER

o Mounted securely

oNot dented or damaged

oNot leaking

SLACK ADJUSTER

oNo more than 1 inch of free play at the push rod with the brakes released.

oNo bent, broken, loose, or missing parts

DRUMS

oNot cracked, broken or dented

oNo oil leaking from inner oil seal, free of debris

LININGS

oNo cracked, broken or missing parts

oNot less than ¼ inch in thickness

DRIVE BRAKES & DRIVE SHAFT

Drive Shaft

Universal Joint

Differential

Reference Items |

Air Line

Service Brake Chamber

Frame

Brake Chamber Mount

Slack Adjuster

TIRES

oProper inflation - company or manufacturer specification.

o No bulges or cuts, can have retreads o Minimum tread depth of 2/32”

RIMS

oNot bent or cracked

oNo welding repairs

LUG NUTS

oNone missing

oTight – no shinny threads, or rust trails

OUTER AXLE SEAL

oNot leaking, no missing bolts

SPACE OR SPACER

oCheck for objects between wheels

oCheck for proper spacing

Lug Nuts

Outer Axle Seal

DRIVE WHEELS

Tire

Bud Rim

Dayton Rim |

Spacer |

Reference Items |

9

Class A CDL

®

®

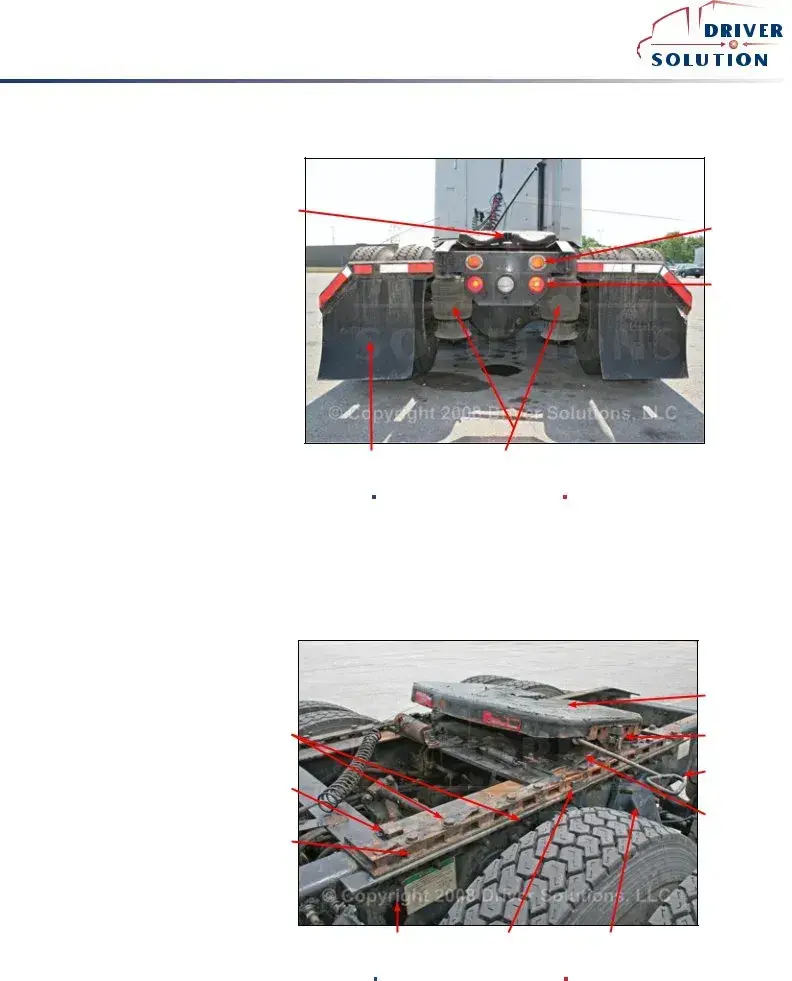

REAR OF TRACTOR

LIGHTS & REFLECTORS o Not cracked, or broken

o Working and proper color

SPLASH GUARDS

oNot missing or torn and properly mounted

Locking Jaws |

|

|

Reflectors |

|

Lights |

Splash Guard |

Air Bags |

Reference Items |

MOUNTING BOLTS

oNone missing or broken

RELEASE ARM

oNot bent, broken, or damaged

oEngaged in the lock position

LOCKING PINS

oNo missing or broken parts

oEngaged and locked

PLATFORM

oSecurely holds skid plate

oNot cracked, or broken

SKID PLATE

oMounted properly on the platform

oProperly greased

oTilting freely

Mounting Bolts

Slide Stops (all 4 corners)

COUPLING SYSTEM

Skid Plate |

Pivot Pin |

Release Arm |

Platform |

KING PIN |

Welds |

oNot broken, bent, or damaged

APRON

oNo bends or damage to visible portions

GAP

oCheck that the trailer apron is lying flat on the fifth wheel skid plate

Frame |

Slide Locking Pin |

Spring Mount |

JAWS |

Reference Items |

|

|

|

|

o Check that the locking jaws are fully |

|

|

closed around the shank of the king pin |

10 |

|

Key takeaways

When filling out and using the Pre Trip Inspection Checklist form, keep these key takeaways in mind:

- Thoroughness is essential. Inspect every part of the vehicle, including lights, brakes, tires, and fluid levels. A detailed inspection helps ensure safety on the road.

- Document everything. Record any issues you find on the checklist. This documentation can be crucial for maintenance and legal purposes.

- Be consistent. Make the pre-trip inspection a routine part of your travel preparations. Consistency helps catch potential problems before they become serious.

- Communicate findings. Share any concerns with your team or supervisor. Open communication about vehicle conditions can prevent accidents and improve safety.

Similar forms

The Pre Trip Inspection Checklist form is essential for ensuring the safety and functionality of vehicles before they are used. Several other documents serve similar purposes in various contexts. Here are five such documents:

- Vehicle Maintenance Log: This document records all maintenance activities performed on a vehicle, including oil changes, tire rotations, and repairs. Like the Pre Trip Inspection Checklist, it emphasizes the importance of regular checks to maintain safety and performance.

- Daily Vehicle Inspection Report: This report is completed at the beginning of each day to assess the condition of a vehicle. Similar to the Pre Trip Inspection Checklist, it focuses on identifying any issues that could affect safety during operation.

- Articles of Incorporation: This form is necessary for establishing a corporation in Washington, similar to the Pre Trip Inspection Checklist, as it provides essential details about the business structure and can be found at Forms Washington.

- Safety Inspection Form: Used in various industries, this form evaluates the safety of equipment and work environments. It shares the same goal as the Pre Trip Inspection Checklist: to prevent accidents and ensure compliance with safety standards.

- Incident Report Form: This document records details of any accidents or near misses involving vehicles. While it serves a different purpose, it complements the Pre Trip Inspection Checklist by highlighting the importance of safety measures and inspections in preventing incidents.

- Equipment Checklists: These are used for various types of machinery and tools, ensuring they are in proper working order before use. Like the Pre Trip Inspection Checklist, they help prevent malfunctions and promote safe operation.